The core idea of the generator is to provide plants with nutrition substances through their stems and foliage. This idea derives from fundamental researches and practical experience of using carbonic acid gas for the growth accelerations of plants. The successful formulation of high energetic solid fuel sets the path for developing the idea further and to synthesize a special mineral complex compound designed to to create a controlled atmosphere (a controlled gas medium) in greenhouses.

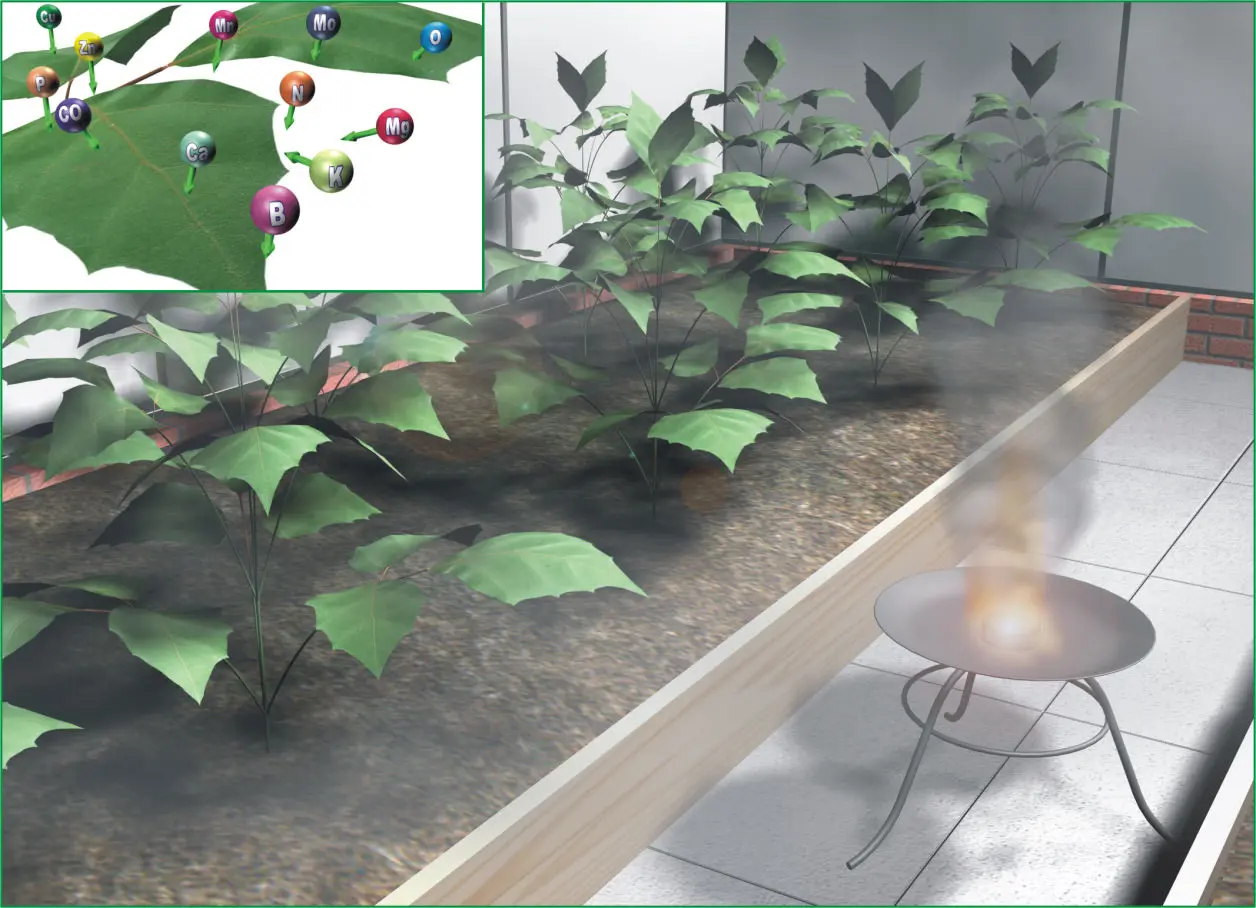

This complex is a heterogeneous mixture of salts and a fuel, during which an aerosol is produced which contains inorganic compounds of potassium, boron, magnesium, zinc, manganese, molybdenum, copper, carbon dioxide, nitrogen and water vapor. A technical means for aerosol production is a generator within which the aerosol is produced from solids pressed from the mineral complex. The generated aerosol optimizes the composition of the environment, characterized by concentrations of oxygen, carbonic acid and nitrogen. The optimization of the gas medium, together with temperature and relative humidity, makes it possible to influence the metabolic activity of the plants. The use of the mineral complex can also create conditions for delayed development of patogenic bacteria.

Advantages of gas medium regulation compared to the traditional plant nutritioning through the root system:

• Aerosol generation with specific parameters of the gas phase and of the solid phase.

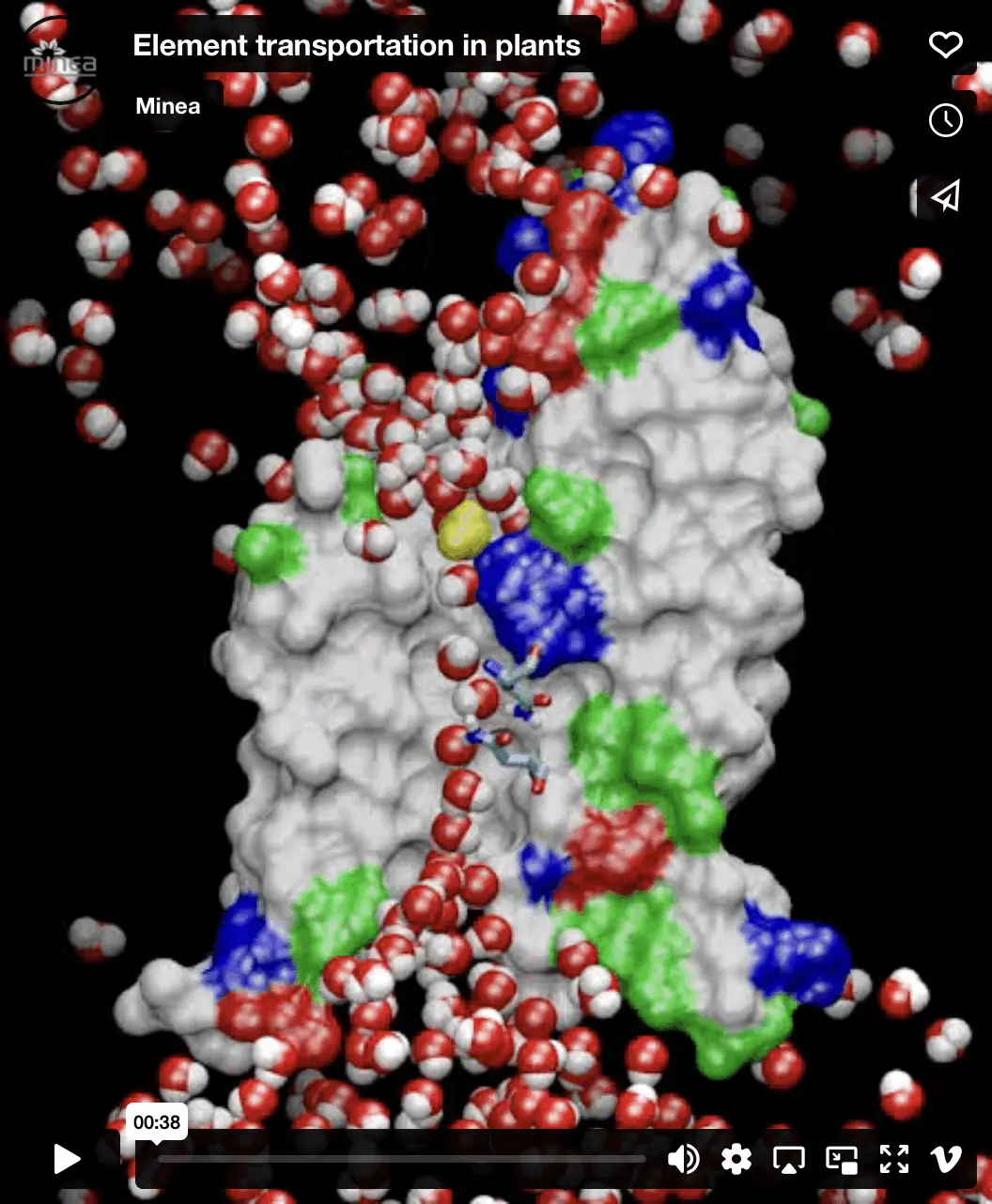

• Intensive gas exchange of the plants with the aerosol which results in the penetration of salt particles of the same / proportionate size as the nano particles into plants.

• Chaotic motion of the nanoparticles in the gas aerosol medium which allows them to condensate on any surface.

• Drastic reduction of the mineral fertilizers amount traditionally added to the root system. As a result only correcting amounts of fertilizer are added.

• The process for controlling the gas medium increases the production efficiency.